No products in the basket.

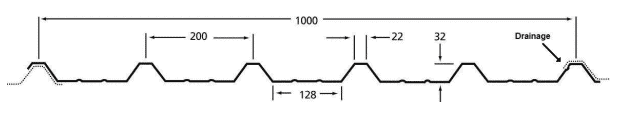

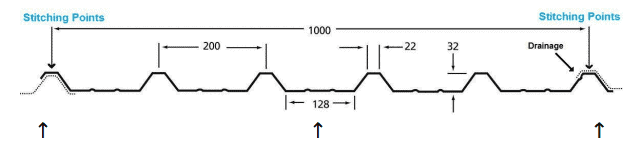

Fixing our box profile sheeting is quick and easy, we advise you to overlap the drainage side of the sheet `as pictured` the groove drives any water away which is trying to get under the lap

The spacing of the purlins will depend on the thickness of the sheets used. As a guide the maximum spacing of purlins we would recommend for 0.5mm gauge sheets is 1200mm, were as the 0.7mm gauge can be spanned upto

1600mm and sometimes further depending on the conditions. The purlins should be a minimum of 50mm in width in order to screw you sheeting easily and quickly.

The laying of the sheets should commence from the eave and towards the prevailing wind (Primarily Left to Right). The side laps will then be away from the wind preventing water from being forced into the lap.

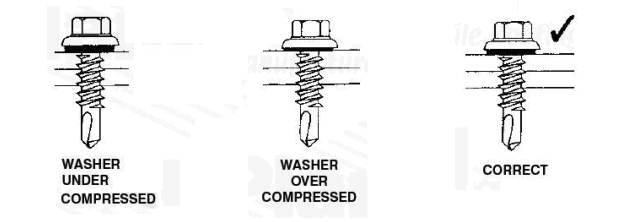

Self drilling tec screws are the most effective method for fixing down the sheets. These can be used for Timber, Steel Purlins, Heavy Section. The sheeting is normally fixed in every other trough but in open areas where the wind is more severe fixing in every trough is recommended. Stitcher fixings are used for the overlaps every 500mm is suitable

Mastic Butyl strip is the recommended sealant for use on profiled steel roofing and cladding projects. Used within the side and end laps of the roof sheet (not normally necessary on wall cladding) these sealants offer excellent performance when compressed.Commonly used in 6 x 5mm or 3 x 9mm bead sizes, this sealant is supplied on a roll with paper backing strip for ease of application.